The main implementation standards

GB/T 3836.1-2021 Explosive atmospheres – Part 1: Equipment – General requirements

GB/T 3836.2-2021 Explosive atmospheres – Part 2: Equipment protected by flameproof enclosure "d".

GB/T 3836.4-2021 Explosive atmospheres – Part 4: Equipment protected by intrinsically safe type "i".

NB/T 11126-2023 Technical specification for the application of active explosion isolation and suppression devices for coal mines

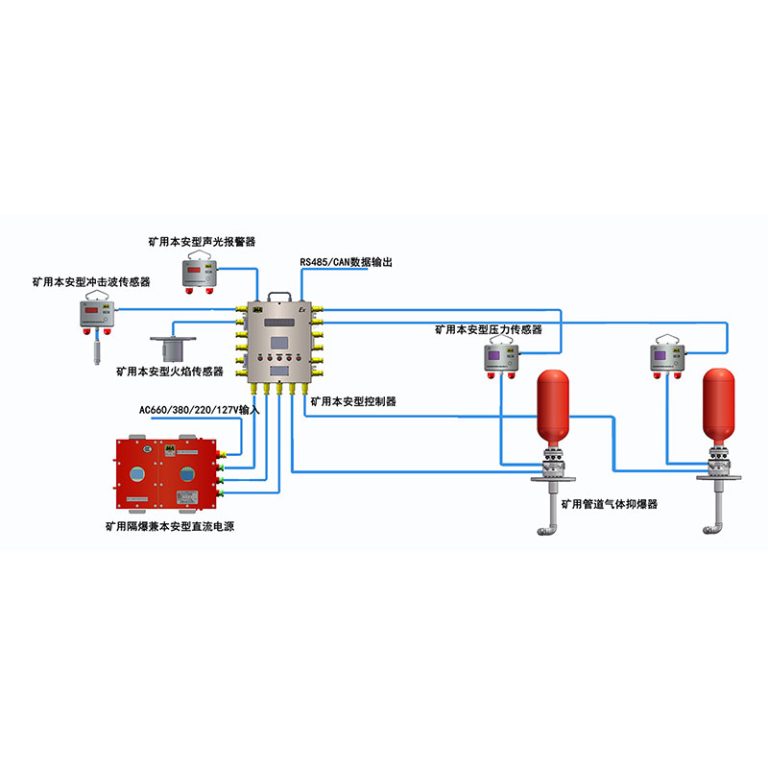

AQ 1079-2009 General Technical Conditions for Automatic Powder Spraying and Explosion Suppression Device for Gas Pipeline Transportation

Product functions and features

| Shock wave signal detection: high-frequency dynamic pressure detector, high frequency response, fast speed, accurate detection of shock wave signal generated by explosion. | Flame signal detection: multi-band spectral detection, using imported photosensitive tubes and military manufacturing quality, to ensure that the flame sensor accurately detects flame signals. |

| Visualized centralized control: Based on the visual comprehensive display, through accurate detection of fire data, equipment status display, equipment failure and other diagnostic analysis, intelligent early warning, troubleshooting and other automatic control are realized. | Accurate analysis and reliable execution: The sensor transmits the detected fire signal to the controller, and the controller reliably drives the action of the explosion suppressor through precise algorithms and accurate logic analysis and judgment. |

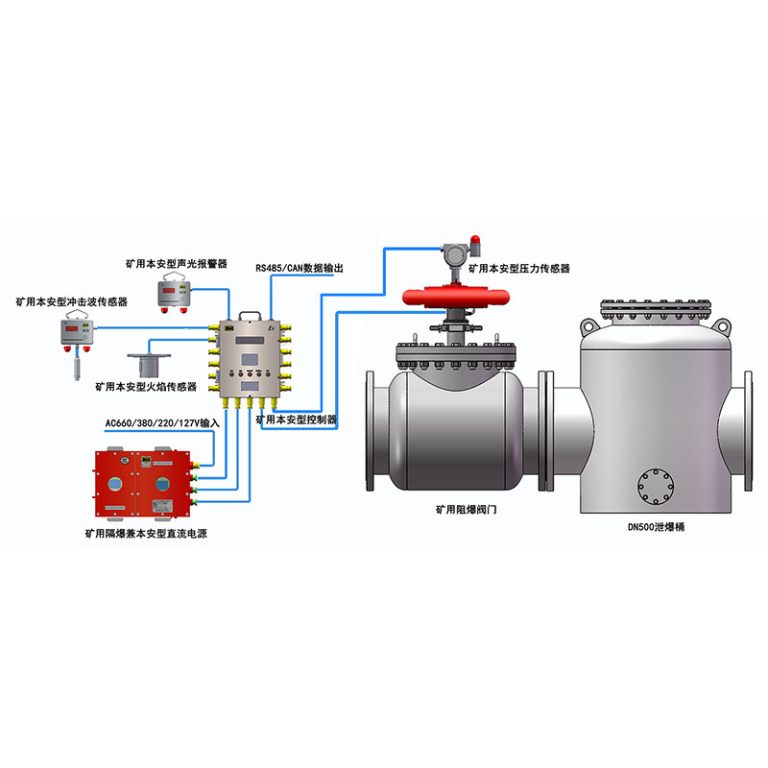

| Multi-channel linkage control: The system can be connected to up to 10 flame sensors and shock wave sensors, and can be driven at the same time to achieve fire extinguishing and explosion suppression control of multiple pipelines. | Intelligent system operation and maintenance monitoring: Visualized monitoring technology is used to intuitively and comprehensively monitor the fire situation of gas transmission pipelines, comprehensively analyze and evaluate subsystems at all levels of explosion suppression, explosion arrest and explosion venting, and dynamically analyze the safety situation. |

- 1 Fast response time of sensor control: T<1ms

- 2. Large-capacity lithium battery for backup: 10000mAh

- 3 Multi-band spectral detection technology: 4-band spectroscopy

- 4. Shock wave detection technology: high-frequency dynamic pressure detection

- 5. Multi-channel sensor monitoring: up to 25 sensors can be accessed

- 6. High fire extinguishing efficiency: aviation ultra-fine dry powder fire extinguishing agent

- 7 Status display

- 8. Anti-fouling and explosion-proof

- 9 Device self-test

- 10. System linkage

- 11. System networking

- 12 step-by-step triggers

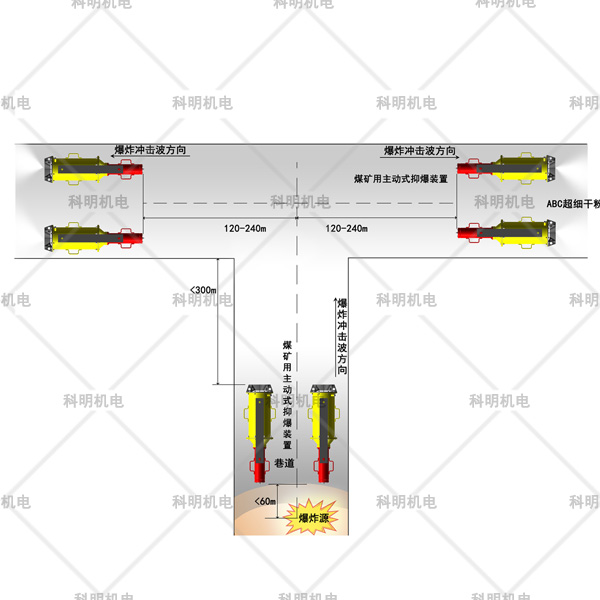

Where the product is installed

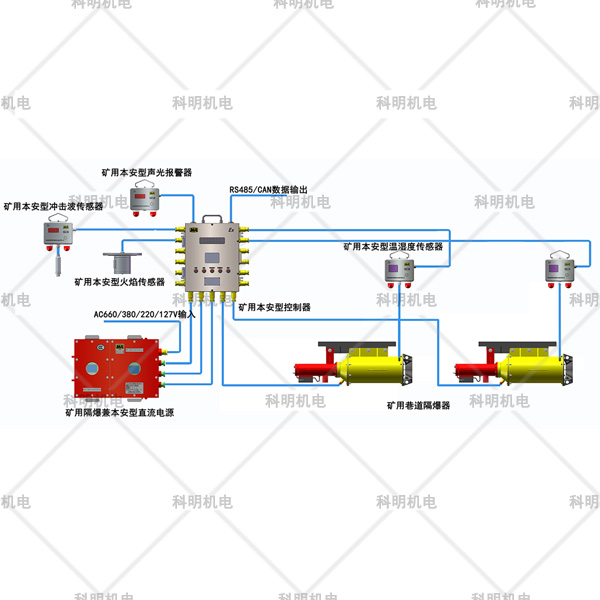

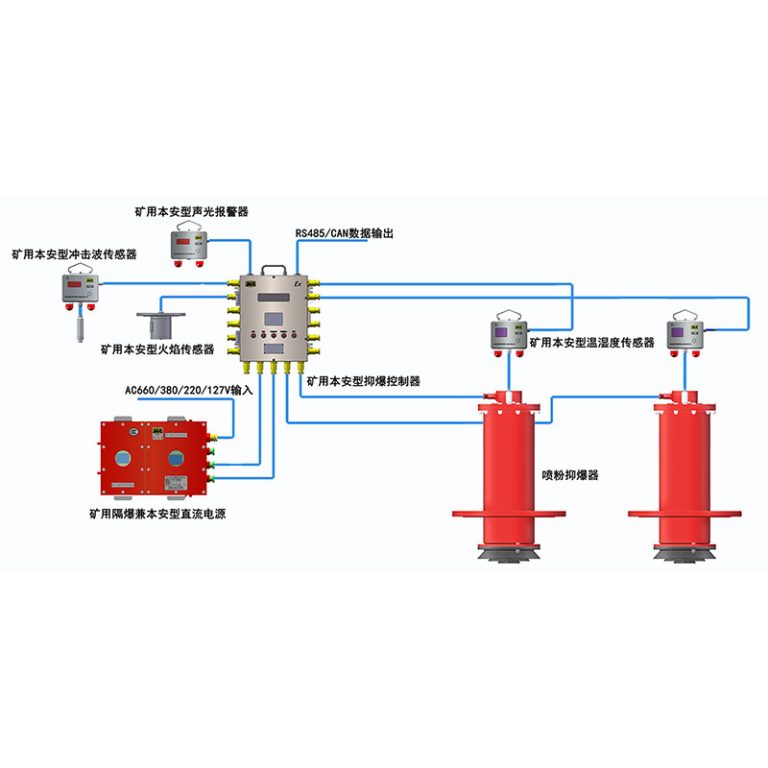

- Active explosion-suppression devices should be installed on the coal mining face, and active explosion-proof devices should be installed on the air inlet and return air roadways;

- For coal roadway and semi-coal rock roadway, active explosion suppression device should be installed on the excavation face, and active explosion-proof device should be installed on the roadway;

- Active explosion-proof devices should be installed in other roadways with gas and coal dust explosion hazards;

- Active explosion suppression devices should be installed in coal bunkers, coal transportation transfer points, crushing coal points, coal unloading points and electrical equipment concentration points.