The main implementation standards

GB/T 3836.1-2021 Explosive atmospheres – Part 1: Equipment – General requirements

GB/T 3836.2-2021 Explosive atmospheres – Part 2: Equipment protected by flameproof enclosure "d".

GB/T 3836.4-2021 Explosive atmospheres – Part 4: Equipment protected by intrinsically safe type "i".

GB 40881-2021 Code for the design of safety assurance system for low-concentration gas pipeline transportation in coal mines

AQ 1072-2009 Technical conditions for water seal fire arresting and explosion venting device for gas pipeline transportation

Standard requirements:

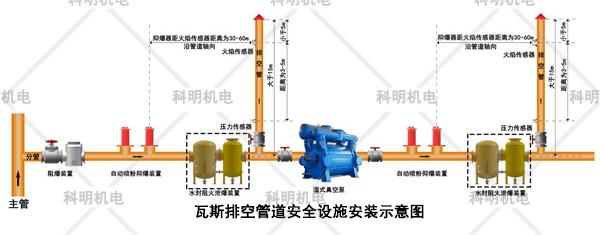

GB 40881-2021 Code for the Design of Safety Assurance System for Coal Mine Low Concentration Gas Pipeline Transmission requires items 4.1 and 4.2:

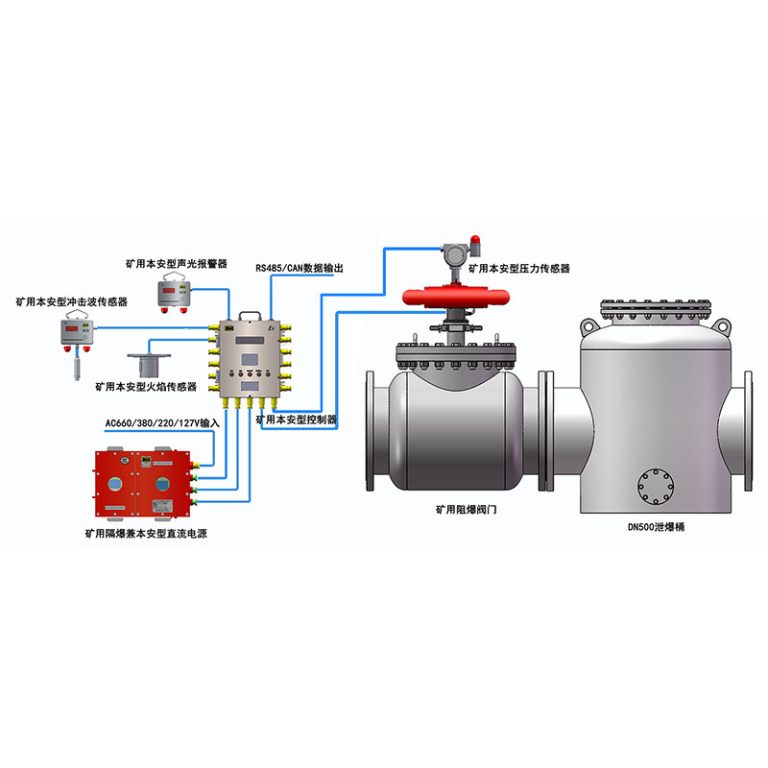

4.1 In the low-concentration gas pipeline transportation system of coal mines, a safety guarantee system shall be installed on the pipelines close to the possible ignition source points (generator set inlet side, ground emptying pipe mouth, spontaneous combustion and easy to spontaneously combust coal seam goaf extraction gas pipe inlet, etc.) to ensure the safety of pipeline transportation.

4.2 The system design should follow the basic principles of "fire and explosion resistance, explosion suppression, multi-level protection, and safety assurance", and the safety guarantee system should be selected from different combinations of fire and explosion venting, explosion suppression, explosion resistance, anti-backflow, safety monitoring and control, lightning protection and other safety facilities according to the different uses of gas transportation.

Schematic diagram of the installation of gas evacuation pipeline safety facilities

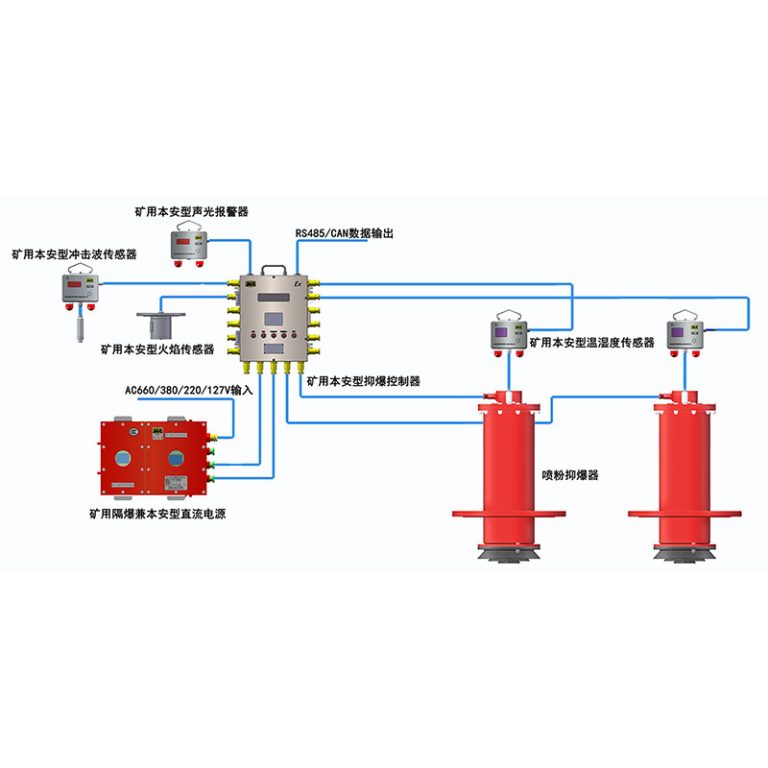

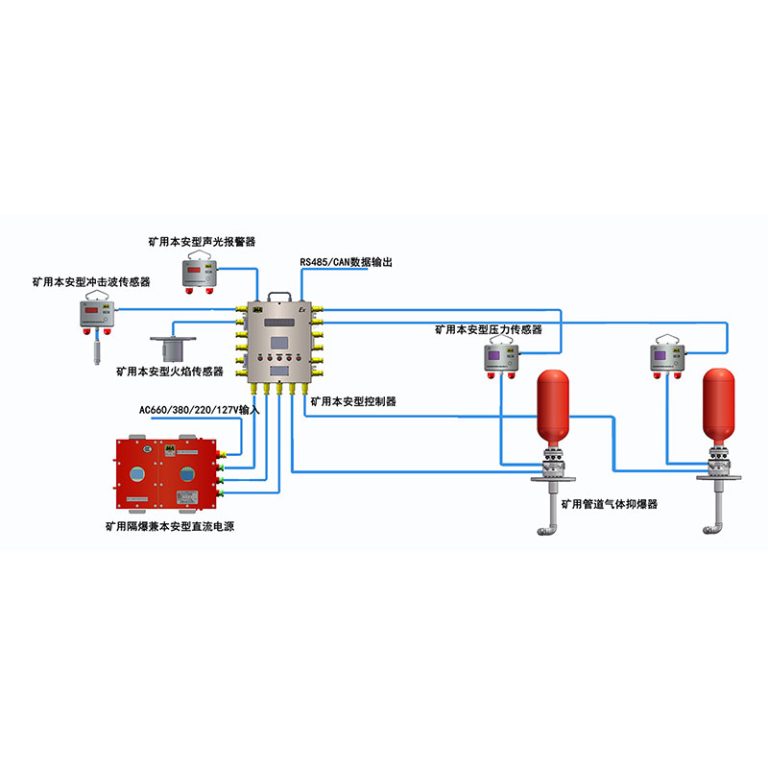

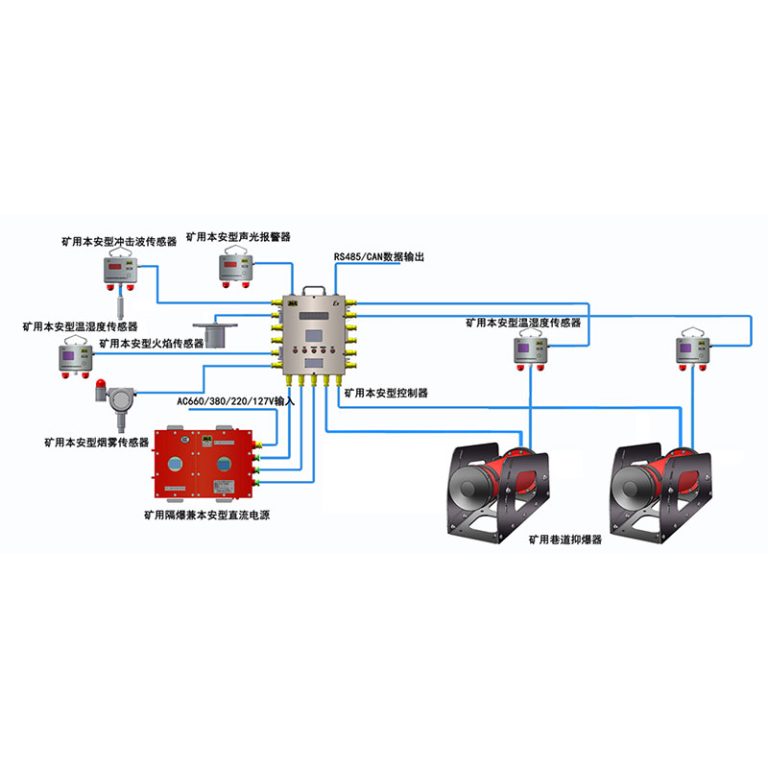

System functions and features

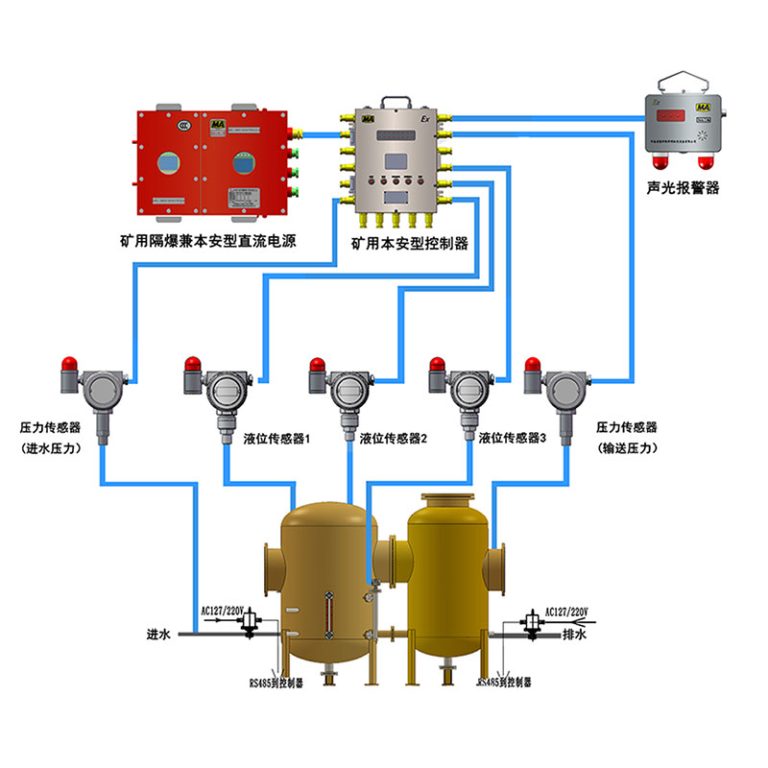

| Water level monitoring and early warning: Magnetostrictive liquid level sensor is adopted, which has strong environmental adaptability, real-time and accurate collection of liquid level data, convenient alarm threshold setting, and multi-signal data upload and sound and light alarm functions. | Pipeline multi-data monitoring: real-time collection of gas pipeline pressure, temperature, and water supply pipeline pressure data, dynamic analysis of system operating environment data, to ensure that the system runs in the best state. |

| Ball valve actuator: The explosion-proof and intrinsically safe electric ball valve is used to make up the water for the system, the pipeline is not easy to block, the opening of the valve body can be dynamically adjusted, and the liquid level is controlled at the effective water seal height. | Optimized structural design: stainless steel plexiglass tube level gauge is adopted, which has high intuitive strength; The bottom of the cylinder is designed with a sewage outlet to facilitate cleaning; Reserved interface for easy connection of negative pressure drainage equipment. |

| Visualized centralized control: In addition to the real-time observation and display of various parameters at the device site, the system uploads the data in real time, and the status of the device can be detected through the monitoring center. | Intelligent system operation and maintenance monitoring: Visualized monitoring technology is used to intuitively and comprehensively monitor the fire situation of gas transmission pipelines, comprehensively analyze and evaluate subsystems at all levels of explosion suppression, explosion arrest and explosion venting, and dynamically analyze the safety situation. |

- 1. Accurate liquid level collection: 3 sets of liquid level sensors

- 2. Large-capacity lithium battery for backup: 10000mAh

- 3. Precise water level control: flameproof and intrinsically safe electric ball valve

- 4. Safety threshold explosion venting: 90~120Kp accurate explosion venting

- 5. Pipeline multi-data monitoring: temperature, positive and negative pressure, water pressure, etc

- 6 multi-channel output control: control the action of 5-way electric ball valve

- 7. High pressure of the container: the design of the upper and lower heads ensures the pressure

- 8. Structural optimization: easy to discharge, negative pressure drainage, and manual self-replenishment of water discharge

- 9. Plexiglass tube level gauge: high visual intensity

- 10 Material control: Stainless steel material is preferred

- 11. Multiple data uploads: RS485/CAN communication

- 12. System intelligent early warning: comprehensive analysis and evaluation dynamic display