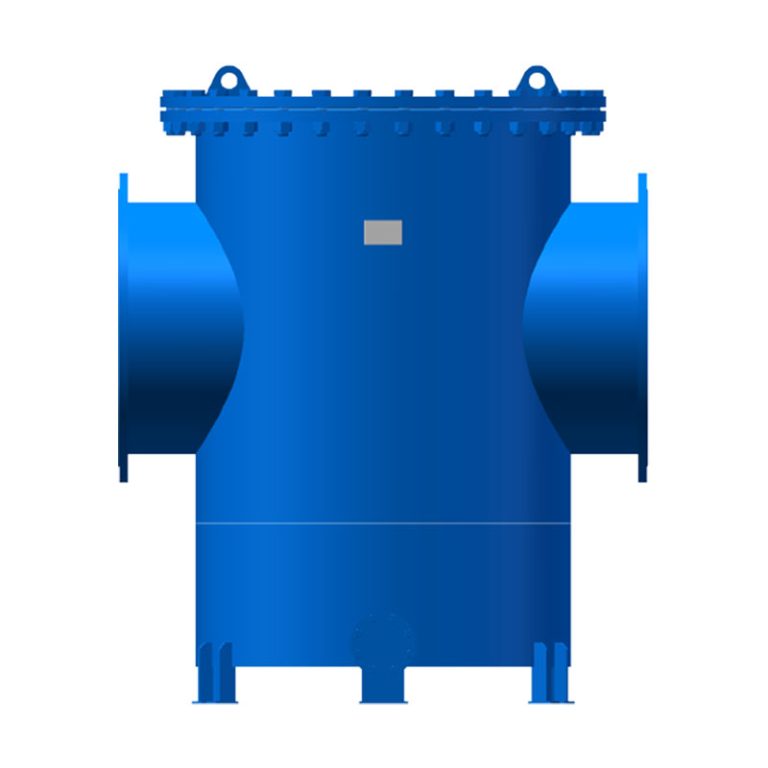

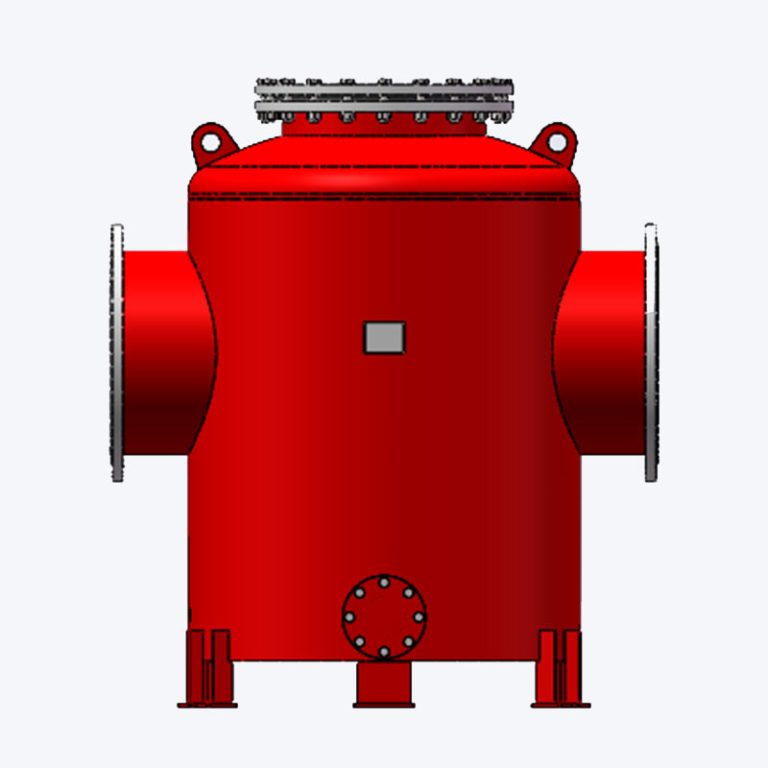

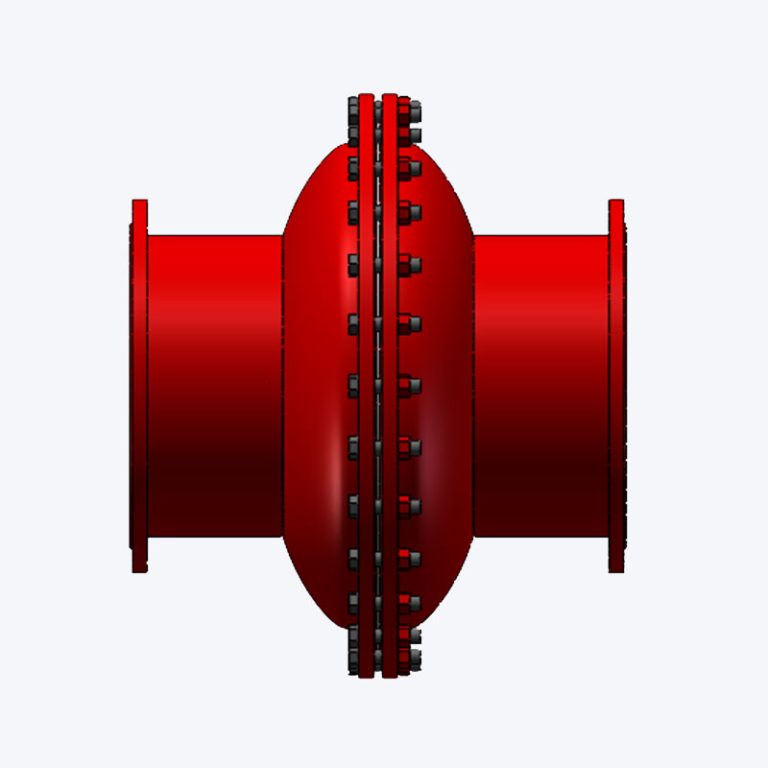

Product Description

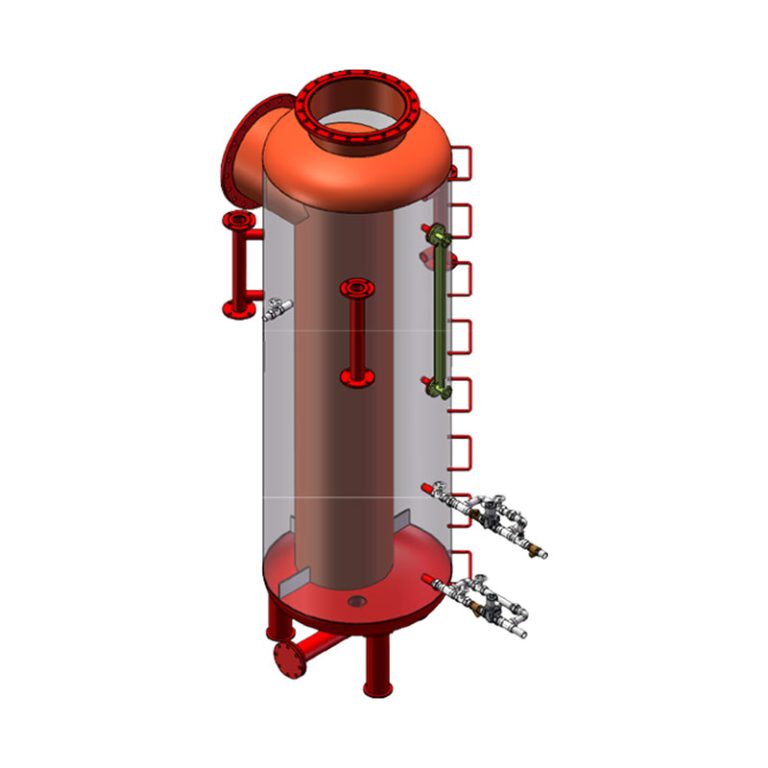

FT series wire mesh filter is an important part of gas transmission, generator set, gas transmission and distribution system, usually installed in the air inlet section of the equipment, used to filter out dust, impurities and other dirt in the transmission pipeline medium, to ensure the long-term normal operation of downstream system equipment; It can be used with various gas flow meters and pressure regulating devices.

a) Ambient temperature: -20°C~45°C;

b) Ambient atmospheric pressure: 80Kpa~106Kpa;

c) Ambient relative air humidity: ≤95% (25°C);

d) Gas working pressure: ≤30Kpa;

e) Applicable medium: coal mine gas gas, gas, etc.

Technical Parameters

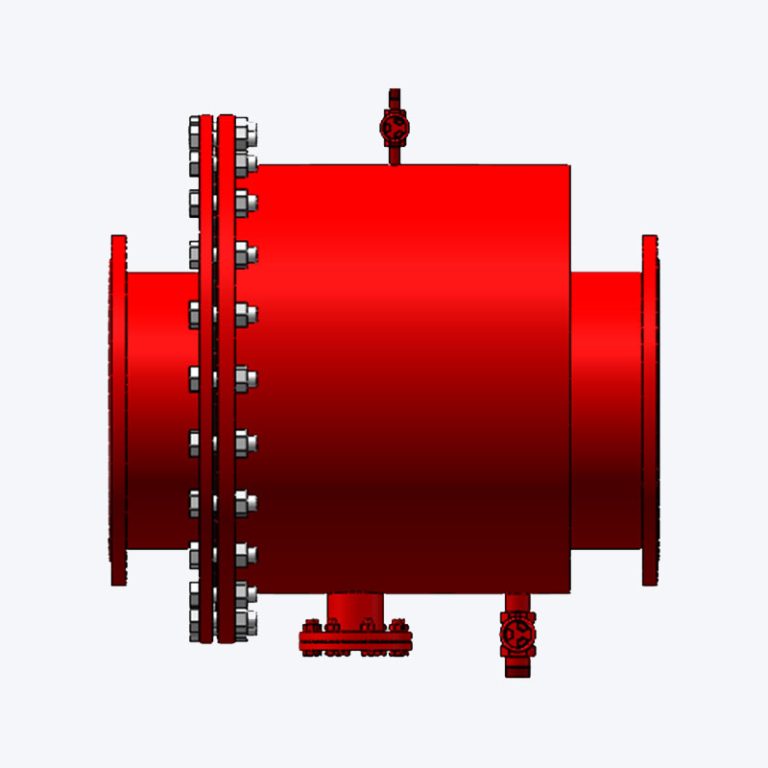

a) Flange standard: GB/T9124.1-2019;

b) housing material: Q235-A;

c) Filter element material: 304 stainless steel;

d) Specifications and models (see Table 1).

| Specifications and models | Equipped with piping | Maximum flow rate M3/H | Pressure loss | Filtration accuracy um | Nominal pressure Mpa |

| FT-100 | Φ108 | 400 | ≤2 | 50 | 0.6/1.0/1.6/2.5 |

| FT-150 | Φ159 | 850 | |||

| FT-200 | Φ219 | 1600 | |||

| FT-250 | Φ273 | 2500 | |||

| FT-350 | Φ377 | 4800 | |||

| FT-400 | Φ426 | 6100 | |||

| FT-450 | Φ478 | 7700 | |||

| FT-500 | Φ478 | 9500 |

Use and maintenance

- According to the use conditions, determine the sewage discharge cycle, so as to discharge the stagnant water and impurities in time;

- When the filter screen is blocked by dirt and the pressure loss increases significantly, it should be cleaned in time, and replaced in time if it is damaged;

- Use kerosene or clean tap water to clean, and carefully remove the dirt with a non-metallic brush until the filter element is as clean as ever;

- When cleaning or replacing the filter element, the inlet and outlet valves of the filter should be cut off first, and the dangerous gas medium in the filter should be replaced with nitrogen, and the dangerous gas medium should be discharged

to a safe area; - After each cleaning, the sealing performance should be re-checked, and then the air in the filter should be replaced with nitrogen after confirming that there is no leakage, and then the operation can be continued.